Specifications

NB-330 Automactic Warm Pad forming Machine

1.Produce warm pad automatically

2.New type

3.Easy to operate and change mold

NB-330 Automactic Warm Pad forming Machine

Let this winter -- warm forever!!

^ - ^

Main technical parameters:

|

No.

|

Items

|

Technical parameters

|

|

1

|

Cutting frequency

|

(15-35times/min)1—4pcs/time

|

|

2

|

Capacity

|

5400pcs/h(according 3pcs/time,30time/min)

|

|

3

|

Max sealing area

|

330×160(mm2)

|

|

4

|

Stoke

|

Standard 60—160mm

|

|

5

|

Section size

|

Standard size:130×100mm

Reference size:128×96 95×70 90×70

(can design according client’s requests)

|

|

6

|

Weight of each pcs

|

Can be design according the requirements of customer

|

|

7

|

Packaging material

|

Non-woven fabric 0.15—0.5×330mm

Gummed paper film 0.02—0.35×330mm

Diameter of scroll 70—76mm

|

|

8

|

Heating power consumption

|

Up and down heating of sealing part:1.5KW

|

|

9

|

Main motor

|

Y90L—6 1.5Kw

|

|

10

|

Pimp capacity

|

>0.2m3(provide by yourself) pressure:0.6—0.8Mpa

|

|

11

|

Mold cooling

|

Tap water or recycle water 50L/h

|

|

12

|

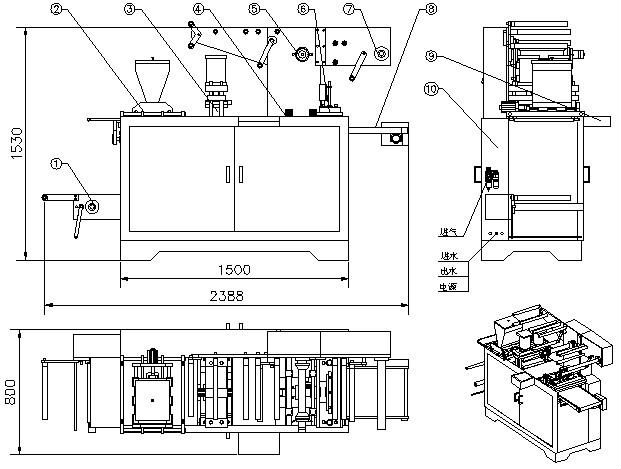

Dimension

|

2400×800×1500(L×W×H)

|

|

13

|

Weight

|

900kg

|

Machine Structure Diagram

1,Fabric holder 2,feeder 3,sealing 4,clip traction 5,sticker holder

6,die cutting 7,waste collector 8,output 9,PLC 10,structure

1,Adopted trasmission device such as gear, screw,etc.Each mold will mover right and left in the machine guide rail by twirling the giggle bars. This makes the machine can package different size products and expands the scope of the machine’s application and debugs the machine easier.

2,The stoke is adjustable between 20-160mm.

3,Adopted up and down heat sealing, only by 150°C up heating and 100°C down heating can seal the fabric with the sticker.Uniform temperature, strong sealing and high quality save energy and ensure the sealing quality.

4,Adopted cam and wheel transmission way to drive the heating plate move up and down make the machine working more stable.

5,By pushing plate type feeding way, and making the material molding on the non-waven fabric directly,makes it measure stable without scattering phenomenon.

6,Using the transmission device such as eccentric wheel and moving ring, and using of die cutting mold through special process, ensure long service life of die cutting mold, and also ensure cutting down the product without burrs, wiredrawing phenomenon. .

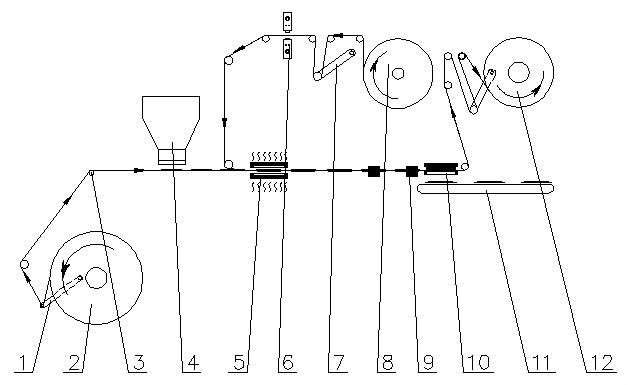

1,feeding film stick 2,non-woven fabric film 3,transfer roller 4,feeder

5,sealing 6,register 7,feeding film stick 8,gummed paper film

9,clip 10,die cutting 11,conveyor 12,waste material recycling

|